CHƯA CÓ THÔNG TIN TIẾNG VIỆT

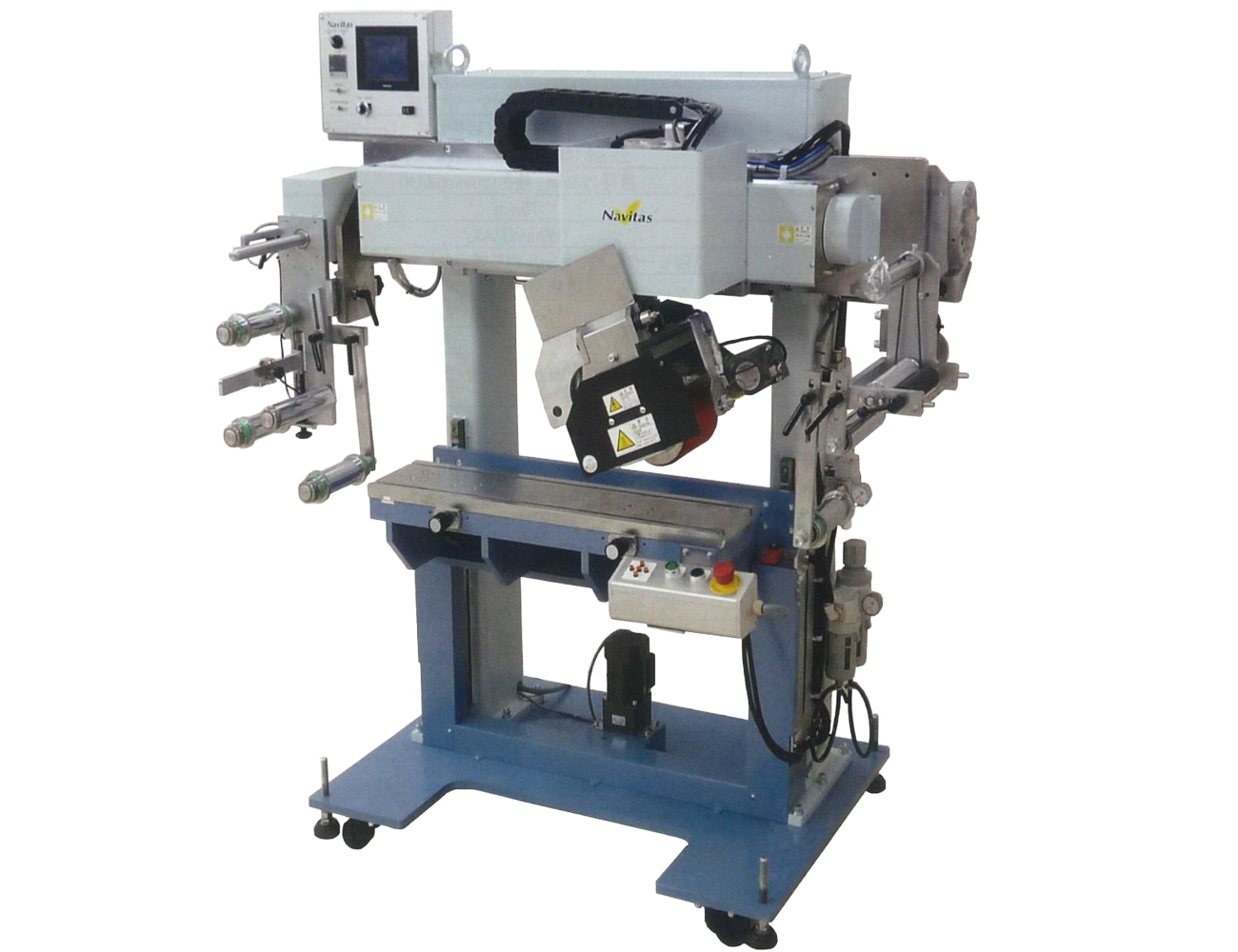

1. Maximum transfer size: (W) 130mm (L) 550mm

2. Thermal transfer section:

| Stamping pressure |

3,927N ( 400 kgf ) *** @0.5MPa air pressure |

| Stamping system |

Air cylinder direct pressure servo system |

| Transfer roll travel driving |

3-phase motor driven ball screw ( inverter-controlled) |

| Transfer speed |

20 to 300 mm/sec |

| Transfer roll travel stroke |

up-down : 75 mm

left-right : max 630 mm ( variable ) |

| Transfer roll size |

(Dia.) 125 mm (max length) 150 mm |

| Heater |

Far infrared |

| Temperature control |

electronic temperature control

Room temperature to 260 ℃ |

| Difference to be compensated |

25 mm ( at angle of inclination 25 ) |

| Shut height |

0 ~ 300 mm ( variable ) |

3. Foil Feeder Unit

| Foil tension control |

Automatic foil tension control unit |

| Foil winding system |

3-phase motor driven ( inverter-controlled ) |

| Foil feed control |

Timer feeding / photoelectric |

| Max. Foil width |

170 mm |

4. Power supply: 3-phase 200V 50/60Hz approx.4.8kW

5. Air source: approx.6N L / cycle ( @ 0.5MPa air pressure )

6. Machine dimensions: (W) 1,650 mm (D) 800 mm (H) 1,635 mm **area of base plate : 200 mm×800 mm

7. Weight Approx:. 500 kgf

OPTION

| ◇ Rotary jig unit |

◇ Slide table (automatic or manual) |

| ◇ Foil holding unit |

◇ Turning table |

| ◇ Foil removing unit |