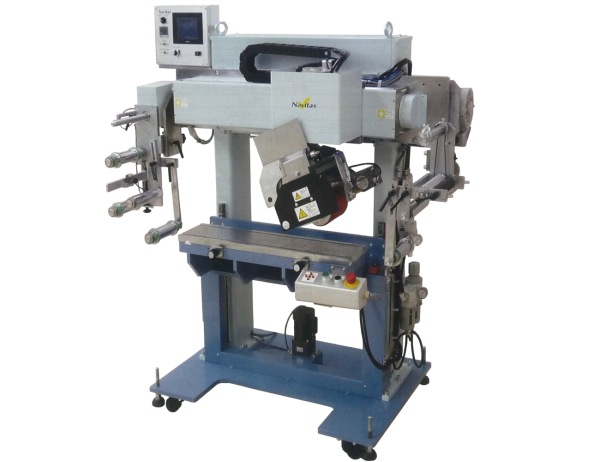

- Possible for changing program and developing inline easily by adopting commercially available sequencer.

- Possible for setting the zone of temperature for processing

- Prevent the occurrence of defective by sounding the alarm and stopping the machine in case of exceeding the range of heater plate temperature

- Using data memory system —- store data of 10 setting for each screen

- Easy foil setting —- One touch operation without any tools, cantilever type foil feeding unit

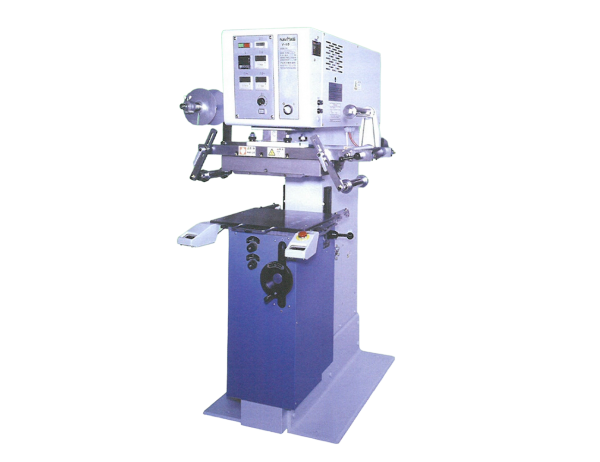

SPECIFICATION

| 1. Stamping unit | |

| ① Stamping system | Pneumatic double toggle type |

| ② Stamping pressure | 800kgf |

| ③ Depth from the hot plate center | 165 mm |

| ④ Opening between table and hot plate | 0 ~ 410 mm |

| ⑤ Slide table dimension | (W) 300 mm (D) 300 mm |

| 2. Hot plate unit | |

| ⑥ Hot plate dimension | (W) 200 mm (D) 120 mm |

| ⑦ Hot plate stroke | 65 mm |

| ⑧ Heater | Cartridge heater, 2 pcs. 0.7kW |

| ⑨ Temperature control | Room temperature ~ 275℃

(controlling with microcomputer-mounted exclusive temperature controller) |

| 3. Foil feeder unit | |

| ⑩ Foil feed system | Motor-driven cantilever type with hot plate fixed

( Sequencer control ) |

| ⑪ Foil feed time control | 0.00 ~ 99.99 sec ( Sequencer control ) |

| ⑫ Foil feed delay time control | 0.00 ~ 99.99 sec ( Sequencer control ) |

| ⑬ Max. foil width | 120 mm |

| 4. Power supply | AC100V, single-phase 50/60Hz, ab.0.8kW |

| 5. Air source (@0.6MPa air pressure ) | 12.7Nl / cycle |

| 6. Machine dimensions | (W) 700mm (D) 700mm (H) 1,500mm |

| 7. Weight | approx. 120 kg |